Milk producers are constantly looking for new ways to provide value-added products that deliver more in terms of nutrition and taste to consumers. A common trend in the industry is to provide lactose free milk since many people are lactose intolerant and more and more consumers are demanding these types of products.

Enzymes, such as DuPont™ Danisco® Lactase for example, is a common ingredient that needs to be added to milk in order to produce lactose free milk. Enzymes cannot withstand high temperatures so there are two options for adding the enzyme to the milk.

Option #1: add the enzyme prior to UHT treatment. This option allows the enzyme and milk reaction to take place over a 24hr period. It will convert the lactose sugars into other sugars thus making the milk lactose free. This method requires that the conversion take place with raw milk, which has many microorganisms present in its natural flora. These microorganisms will attack the enzyme and damage or kill many, so the amount of expensive enzyme to accomplish the complete conversion is three to four times greater, ultimately increasing the cost considerably. The milk cannot be pasteurized after adding the enzymes for many hours, or the thermal shock will kill the enzyme, thus there is also natural degradation of the raw Milk quality more or less depending on the natural flora of the milk. Once the conversion of lactose is complete the milk can and must be pasteurized. The sugars that are produced from the lactose conversion are also heat sensitive and will develop off colors. They turn pink after some time from thermal processing, thus shortening the sell by date code. This is not a problem for short date code products but is for extended shelf life product (ESL). Therefore, this method is not recommended for any product that is going to have date codes beyond two plus months. Shelf Stable milk absolutely cannot be processed in this way.

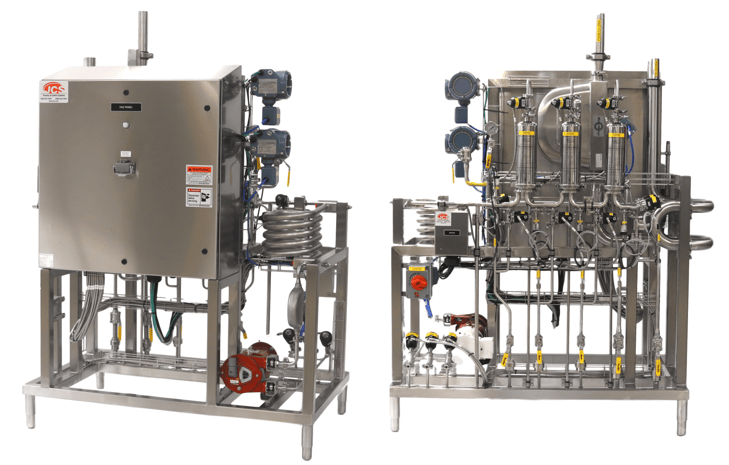

Option #2: is to add enzyme post Pasteurization treatment. This option allows the enzyme and milk reaction to take place over a 24hr period in the package itself. This option can work in conjunction with the JCS UltraBlend™ In this approach raw milk can be processed in a timely manner to prevent deterioration of the milk quality. The milk can be processed for Fresh (Short date Code), ESL (Extended Date Code), or Shelf Stable (For storage non refrigerated with long date codes), and once pasteurized the JCS Continuous Process standardizing in-line blending system will add the precise amount of enzyme for each volume of milk packaged, to assure a complete lactose conversion in the finished package.

Since the enzyme is placed in the milk after pasteurization:

- There is NO competing organisms to damage or kill the enzyme

- There is NO subjection of the thermal sensitive sugars to heat treatment

- There is NO loss of enzyme due to the thermal processing

All of these enzyme friendly facts result in a higher quality finished product that is stable and produced with only 25% of the enzymes necessary in Option #1

Advantages to post Pasteurization treatment

- Improves the quality of the finished product by allowing the raw milk to be processed in a shortened time frame, preventing microorganism deterioration of the raw milk quality

- Improves the finished product shelf life because the converted sugars do not see high temperatures

- Reduce the amount of enzyme needed; enzyme conversion post heat treatment is a much more efficient process, and since the enzymes are expensive, the savings are substantial

- Increases the shelf life of ESL and Shelf Stable lactose free products

Advantages of the JCS UltraBlend™ for Enzyme Standardization

- Quality: Pasteurizing the raw milk prior to Enzyme Dosing prevents the deterioration of Milk in the raw state by the microorganisms of the natural flora

- Cost: of production is much lower due to the improved Efficiency of the enzyme

- Silo Space: is optimized, since there is no need to hold the raw milk after enzyme dosing waiting for the conversion to take place

- Shelf Life: is increased for long life milk due to the fact that the converted sugars are never subjected to the thermal processing

- Yield: production runs of lactose free milk in excess of 75,000G on a single set of filters.

- Minimize Enzyme Loses: The enzyme is blended in real time with RO (reverse osmosis) water to eliminate the need to pre-mix and hold in WIP (work in process) the enzyme and RO water.

- Product Flexibility: the JCS UltraBlend™ for enzyme can be used to produce a variety of lactose free dairy products including but not limited to: Whole Milk, 2%, 1.5%, 1%, Skim, Chocolate Milk, Strawberry Milk, Vanilla Milk, and more.

- Optimized Sequence: the JCS UltraBlend™ for enzyme can be fully integrated into the UHT sequencer so enzyme dosing only occurs when the UHT is processing a product that requires enzyme. The dosing skid responds to the flow rate of the UHT so can operate across different UHT product flow rates

- Production Flexibility: the JCS UltraBlend™ for enzyme maintains a steam barrier with the UHT which permits the JCS UltraBlend™ to be sterile and isolated while other products are running providing maximum production flexibility.

- The JCS UltraBlend™ for enzyme can be sterilized independently to the UHT while the UHT is running other products.

Additional Methods of JCS Production of Lactose-Free Products

Although most of the lactose-free products on the market today are produced on UHT systems, JCS also has the ability to produce lactose-free products in Fresh Dairy Product, using our JCS UltraBlend™. This can be added to normal HTST, or HTST with MST “Long Life Fresh” Dairy Product technology embedded in the HTST.