We Know How

.jpg?width=2000&height=1330&name=11_24_JCS%20Enzyme%20Dosing%20Skid%20(002).jpg)

FLEXIBLE PRODUCTION SCHEDULE WITH THE JCS UltraBlend™ for enzyme

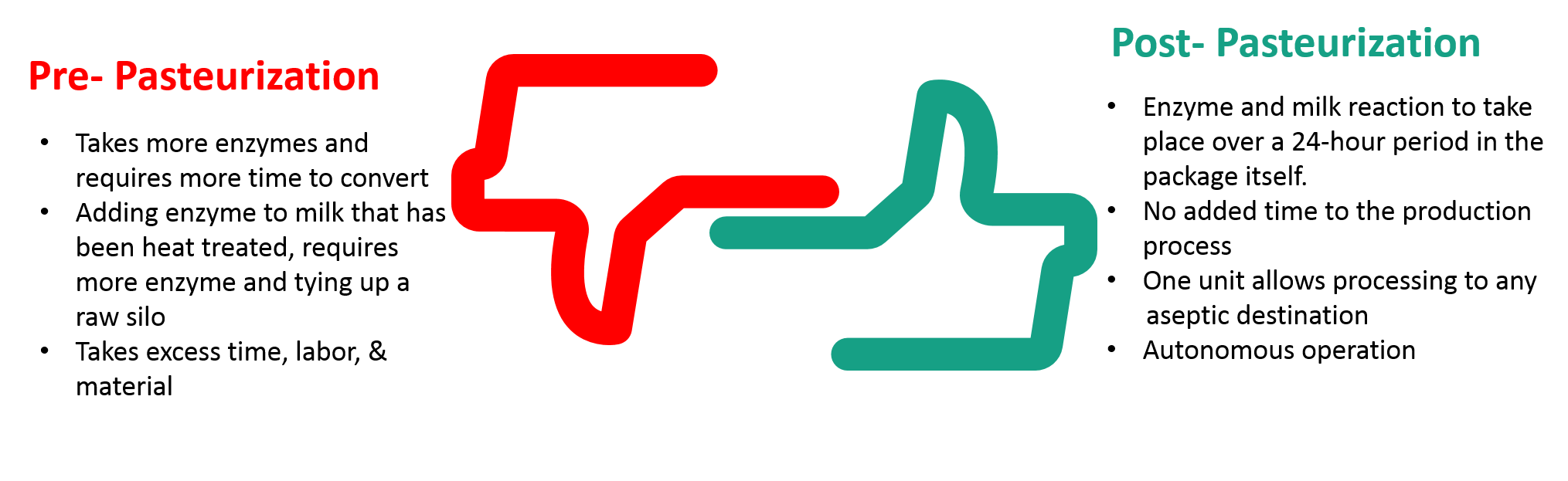

With the JCS UltraBlend™ you can add enzyme post pasteurization treatment allowing the enzyme and milk reaction to take place over a 24 hour period in the package itself. With this approach, some of the benefits are:

Cost Savings: Cost of production is lower due to the improved efficiency of the enzyme and eliminate the need for batching tanks.

Product Quality: Pasteurizing the raw milk prior to enzyme dosing prevents the deterioration of milk in the raw state.

Extended Runs: Production runs of lactose free milk in excess of 75,000G on a single set of filters.

Lactase enzymes are the main ingredient that needs to be added to milk in order to produce lactose-free milk. When enzymes are added, lactase catalyzes the conversion of lactose to glucose & galactose which lactose intolerant consumers can consume.

Options for adding the enzyme to the milk

.png)

The JCS UltraBlend™ can be incorporated on Aseptic/ESL/HTST systems.

JCS Process & Control Systems • 172 Metro Park, Rochester, NY 14623 • p: 585-227-5910 • f: 585-723-3213

© 2026 JCS All rights reserved Site Map