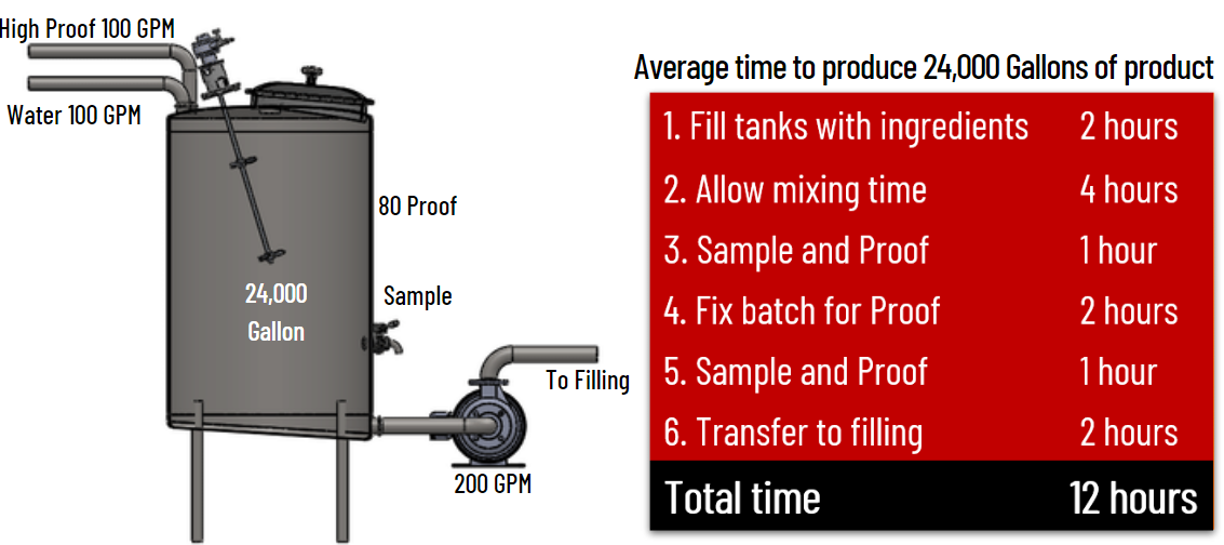

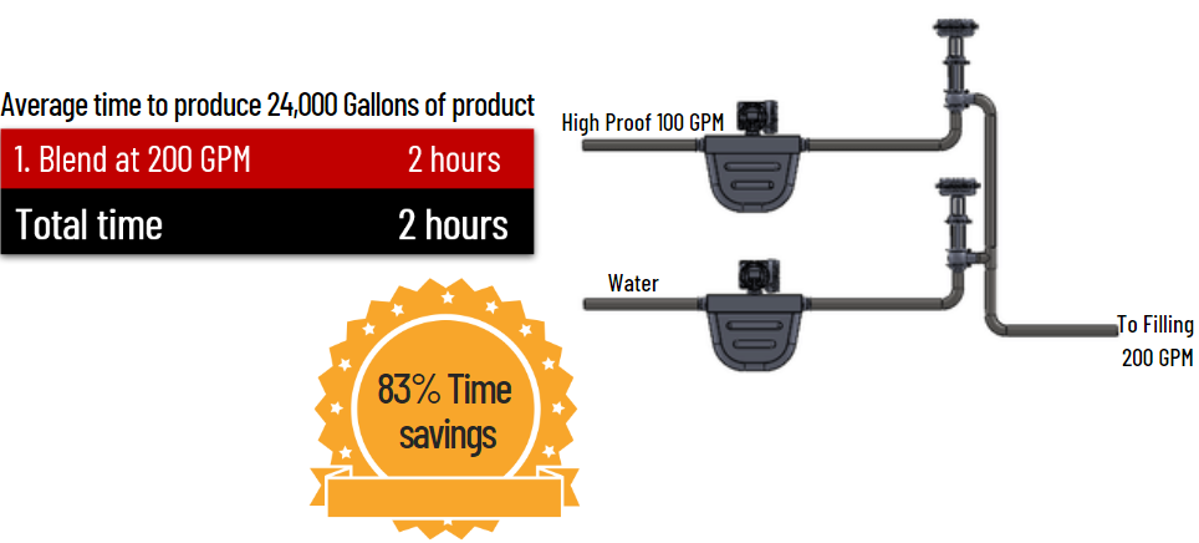

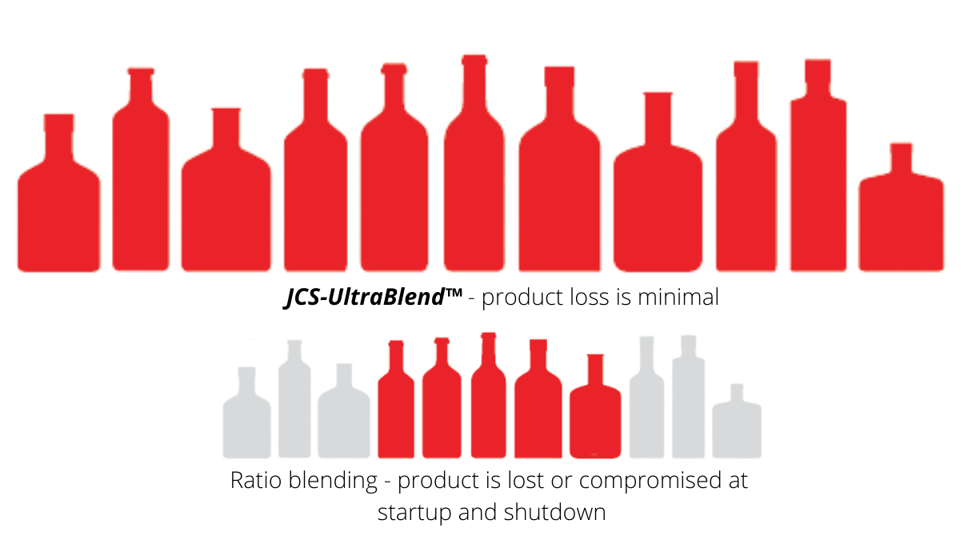

For the spirits industry, the JCS UltraBlend™ is the only system installed, approved by the TTB (Alcohol and Tobacco Tax and Trade Bureau) to continuous blend alcohol spirits to a bottling filler without the use of a bottling tank for proof checking.

We Know How