We Know How

The JCS CIP System is designed to clean each circuit as efficiently as possible, optimized for chemical usage and time.

The standard JCS CIP Sequencer is preprogrammed with 5 step and 7 step CIP processes.

The JCS CIP Sequence is controlled by pinning charts. The pinning is viewable and changeable using Microsoft Excel in real-time. This makes it straight forward to add custom CIP Processes i.e. options for cold water rinse, hot water rinse, etc.

Instrumentation provides accurate control and optimizes the performance. If you measure something, you can optimize it.

Milk, Shake Mix, Ice Cream Mix, Functional Beverages, Plant-Based Beverages, Nut based Beverages, Fruit Juices, Nectar, Tea, Sauces, Purees, and many other types of foods and beverages.

Integration of the CIP system to the different circuits requiring cleaning is critical:

A standard JCS CIP System is integrated for your specific plant cleaning requirements.

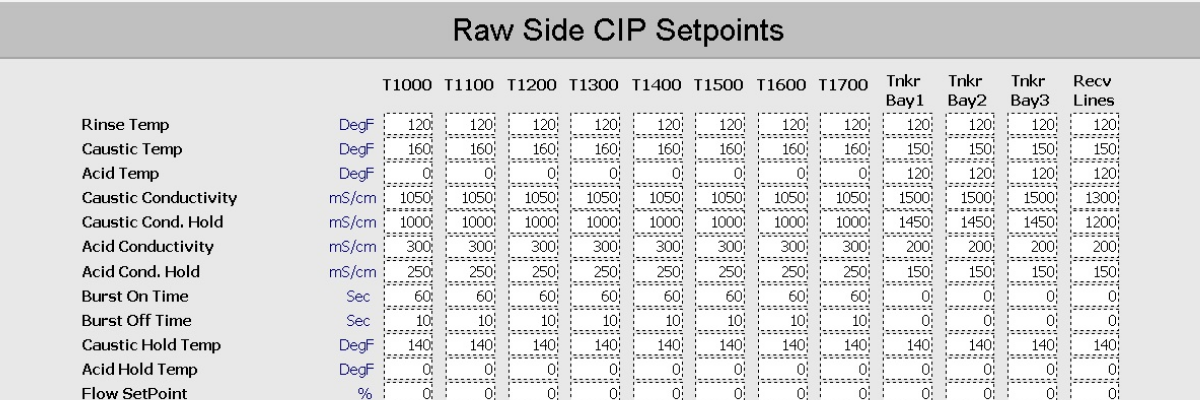

Setpoints can be changed by personal on-site with the approved HMI permissions.

The JCS CIP processes provides optional extended washes for different difficult cleaning loads such as allergens, particulates, titanium dioxides.

The JCS integrated system provides additional safety interlocks between process and CIP. This gives an added level of plant safety so once a circuit has been cleaned it can be tagged as clean. This can ensure that a CIP is completed and not skipped over. Circuits can be time stamped so operators and supervisors can quickly determine when a circuit or tank was lasted cleaned.

.png?width=2400&name=CIP%20reporting%20(1).png)

Continuous monitoring of the CIP Process assures complete and efficient cleaning and can avoid costly production time delays:

An integrated air blow assures:

The CIP system can record all Critical Control Points for each circuit to a database for full CIP reporting.

JCS Process & Control Systems • 172 Metro Park, Rochester, NY 14623 • p: 585-227-5910 • f: 585-723-3213

© 2026 JCS All rights reserved Site Map