We Know How

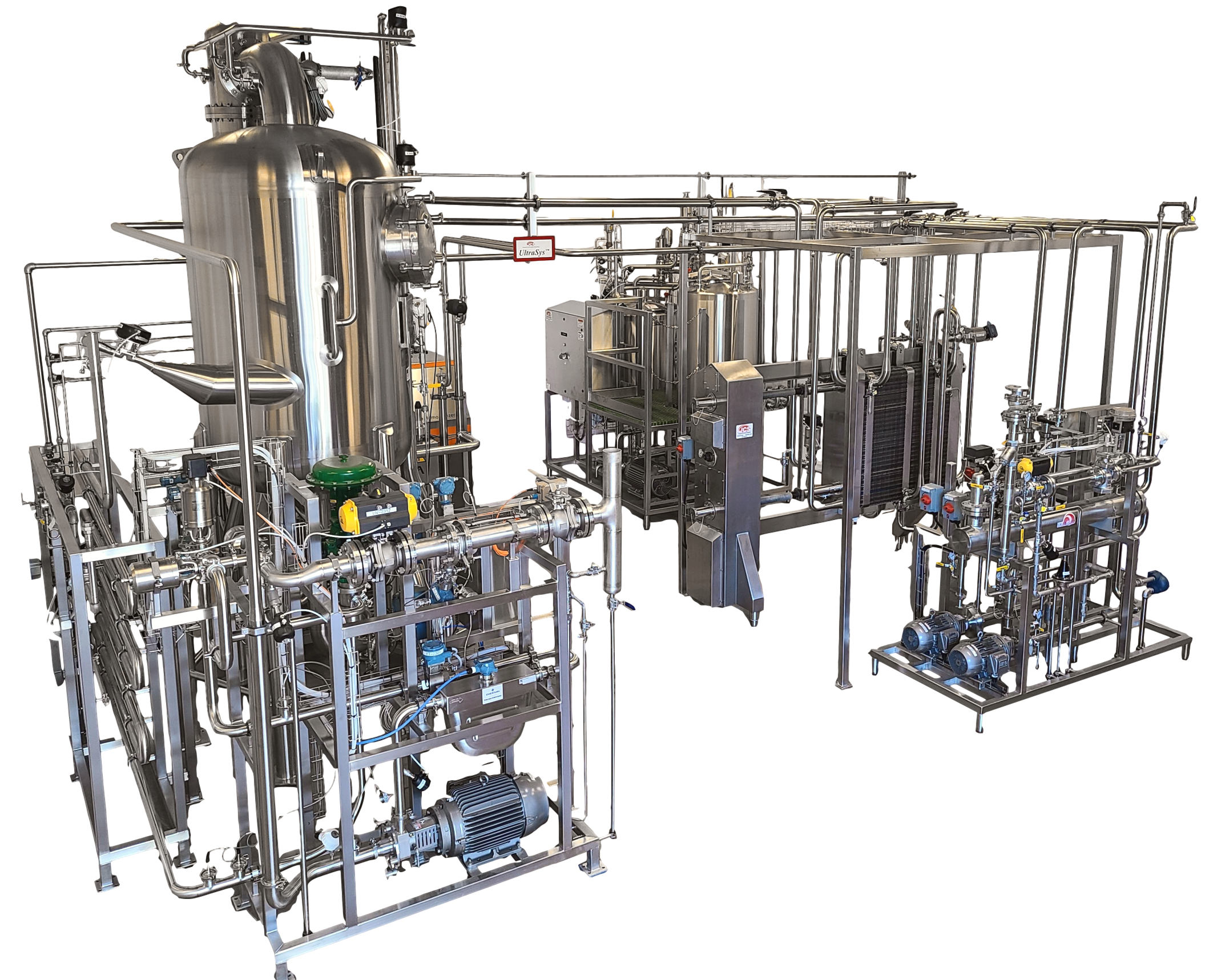

UltraSys™

The JCS UltraSys™ is our unique, direct steam injection UHT / HHST for clean Low Acid processing for Shelf Stable or Extended Shelf Life (ESL) products.

The system uses JCS best-of-breed sophisticated controls that optimize the process for the product that is running to minimize product loss, maximize flavor profile with reduced utility and energy consumption.

The system is installed in flow rates from 8 – 125 GPM throughput.

Designed for production flexibility with a 33% turn down.

The JCS UltraSys™ can process products ranging in viscosity from 1.0 to 300.0 cps.

Milk, Shake Mix, Ice Cream Mix, Functional Beverages, Plant Based Beverages, Nut based Beverages, Fruit Juices, Nectar, Tea, Sauces, Purees, and many other types of foods and beverages.

The JCS UltraSys™ system has Dual Balance Tanks. One tank for water and the other tank for product. This benefits a clean interface change-over process which results in substantially reduced product losses. The JCS proprietary Feed Forward Controls allow for this high degree of load change at any specific time.

The level in the Flash Chamber is maintained at zero, only controlling product in the down leg which minimizes water and product mixing

Product characteristics (thermal, density, cP) are maintained in a database enabling the JCS UltraSys™ to precisely control the mass energy balance of the system for the specific product being processed.

Product Density Monitoring comparing the measurement to the database of the specific product allows the system to precisely know the amount of interface at any time, resulting in increased yields and system performance.

The JCS UltraSys™ can be specified with different heat exchangers based on the specific product requirements.When the system is configured with a plate heat exchanger (PHE):

It is equipped with a hydraulic closure, this provides for much quicker opening and closing of the PHE: 10 minutes or less compared to 2 hours or more.

It is designed with product-to-product regeneration. Compared to an indirect system, this type of direct regen system is:

less complex

has less equipment resulting in less areas of risk and potential failures

improved quality of product as product is maintained typically by 2-3% lower temperatures

reduced energy consumption as product-to-product regeneration is more efficient.

When JCS UltraSys™ is configured with a tubular heat exchanger the design layout accommodates easy swabbing and inspection when allergens are a concern. The system can also flex to higher viscous products. See UltraFlex™.

When JCS UltraSys™ is configured with a spiral heat exchanger the design layout accommodates easy inspection. Additional valving is used to reduce SIP times by heating the media as well as the product. The system can also flex to extremely high viscous products as the Spiral Heat Exchangers can tolerate pressures greater than 3000psi. See UltraFlex™.

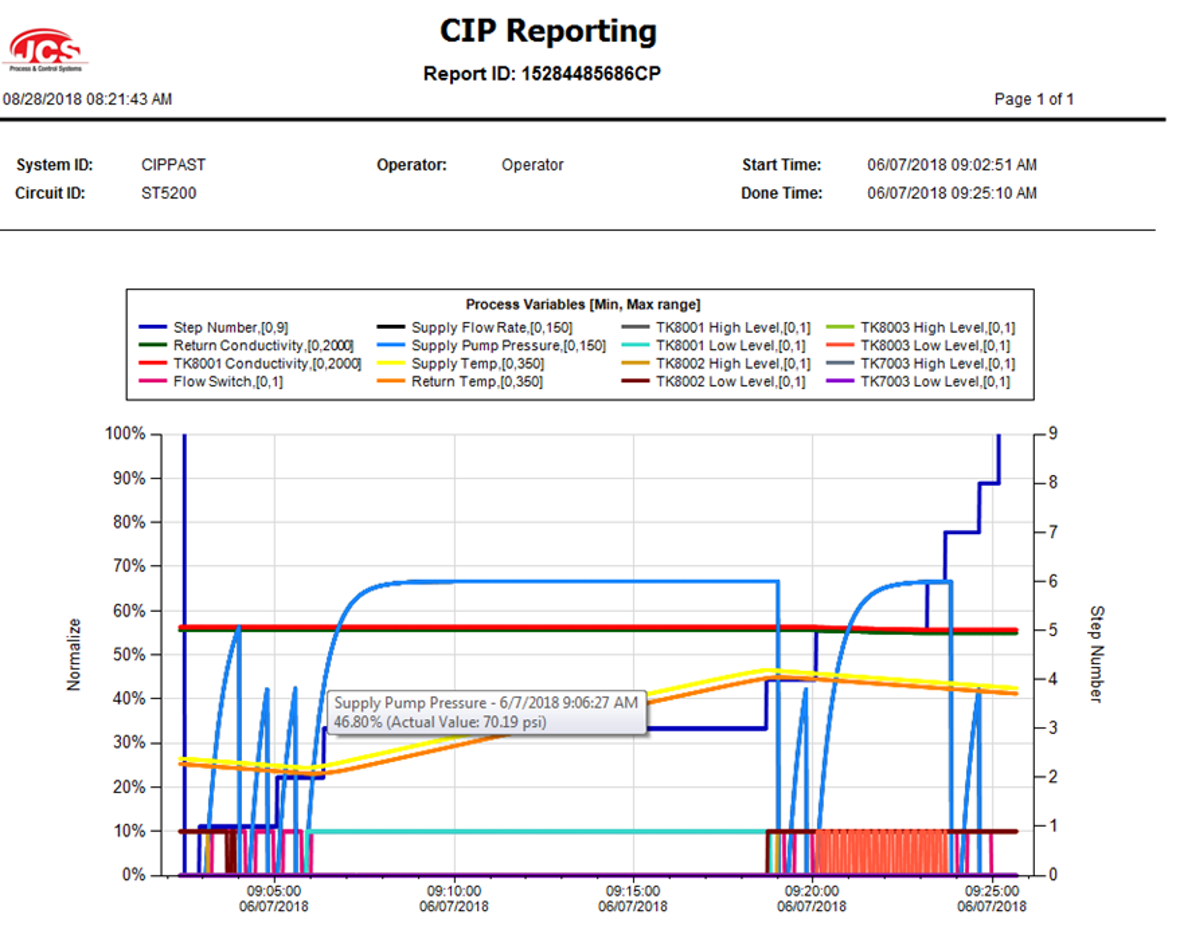

More Data for Quicker Diagnostics

The additional instrumentation on the JCS UltraSys™ provides a wealth of information for quick diagnosis of problems and supports a plant continuous improvement initiative.

There are multiple pre-configured trends, so the operator has the required information at their fingertips

A network diagnostics screen is available to show maintenance where issues are with all components on the Ethernet network

Divert diagnostics are on the HMI for immediate troubleshooting.

The system has many built in self diagnosing alarms to simplify maintenance and operation troubleshooting

HAACP Screen – A single HMI screen displays all of the Critical Control Points (CCP) making the data easily accessible for Quality to review.

Ease of Integration – The Control System provides an Ethernet Connection to the Plant PLC network and provides a protocol for synchronizing control of the Upstream Processor and Down Stream Fillers, as well as the CIP System.

Reporting – Production, SIP & CIP trends can all be stored in a database and then reports generated as needed.

JCS Process & Control Systems • 172 Metro Park, Rochester, NY 14623 • p: 585-227-5910 • f: 585-723-3213

© 2026 JCS All rights reserved Site Map