Data Capture is the first step towards process improvement. No matter the industry that you are in, if you cannot measure it, you cannot improve it. In the Food and Beverage processing industry, this is not an exception. For process control systems, data capture is a vital part of the overall system and is what validates the finished product. JCS has developed a standardized approach to data capture for each control process - batching, blending, clean in place (CIP) systems, and ultra-high temperature (UHT) systems - to record data for regulatory, troubleshooting, process optimization and reporting purposes.

A key factor in the process is to understand what data is important to both a customer’s business operations & what data needs to be recorded per the finished product industry’s regulatory statutes. In close collaboration with the customer, JCS incorporates the collection of customer specific data into the JCS standardized data capture process.

After identifying the data to be stored, the data is normalized and stored to a relational database – Microsoft SQL Server. Numerous benefits exist for using Microsoft SQL Server to store process data – reliability, scalability, recoverability, security, the existence of well-developed tool sets, and most importantly standard interfaces are provided by many ERP (enterprise resource planning) and MES (manufacturing execution systems) systems for plant wide data integration.

Although the database is the centralized component for data storage and retrieval, JCS provides an overall data capture process solution for every project. One of the major advantages of the JCS data capture process is that if the SQL database server becomes unavailable, built-in buffering functionality prevents the loss of process data and a system alert is generated notifying the user of the condition.

In addition to storing process data for regulatory validation, an analysis of the data can indicate where process improvements can be made for overall efficiency to increase output. For example, utilizing JCS standard reports, an analysis of CIP trend data by a plant engineer to determine why a CIP run is taking much longer to complete than prior runs may indicate that the issue is with the duration of the temperature to reach setpoint.

With the data stored to a SQL database, it is available to all who need it – plant operators, supervisors, managers, etc. via the HMI, JCS standardized or custom reports, or other customer specific ERP/MES applications. Utilizing SQL server’s built-in security features protects the data and ensures the data is available to its specified users. With JCS’s systematic approach to data capture the customer can be assured that all relevant data to their process is collected and stored. Armed with industry knowledge of what process data is mandatory and beneficial to the end user, JCS can be relied on to deliver the best data capture solution for your process.

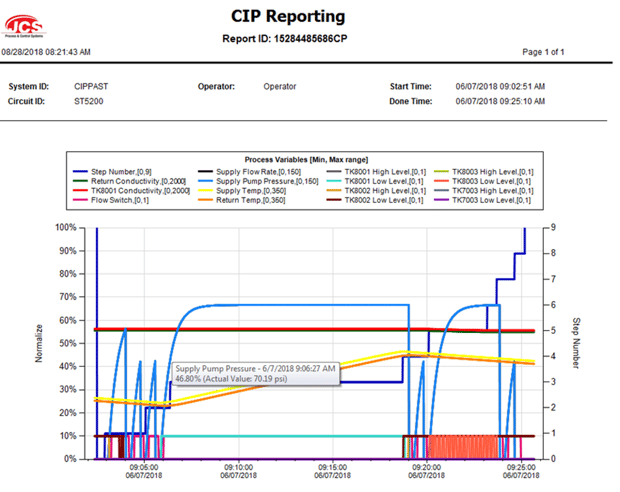

Example of a web-based interactive JCS CIP report which shows key process data (i.e. temperature, pressure, flow rate, conductivity, high/low levels) collected during a CIP.

Example of a web-based interactive JCS CIP report which shows key process data (i.e. temperature, pressure, flow rate, conductivity, high/low levels) collected during a CIP.