As a beverage producer you are regularly evaluating market options for differentiating your aseptic product lines, and that ofttimes requires new or modified aseptic processing systems in your enterprise. Your Staff and Engineering Team will have to answer questions like: How can I choose the appropriate system for my plant? What is the best technology? Can I use only one processing system for all my applications? There is no correct answer for what the best technology is for UHT or HHST design. One technology may be best for one product and not for another. Therefore, the product application should be the driver of your selection. If the wrong technology is selected, the product may not meet proper specifications or quality. The best technology for the application is the one that produces the best product quality at the lowest capital and operating costs.

.png?width=619&name=Social%20Media%20Posts%20(21).png)

The design of a typical aseptic processing system must start with an exploration of the characteristics of the range of products that you plan to process through the system. Once the product formulations have been analyzed, a team of engineers and technical staff will develop the concept for the processor, following a very detailed set of criteria so that the final design can provide you the most flexible process capabilities. Some of the typical factors that are considered during the selection phase are:

Potential of hydrogen (pH)

Food products can be categorized as high-acid (pH < 4.5) or low-acid (pH>4.5). In general, indirect UHT processors that utilize tubular heat exchangers are better suited for processing high-acid products, whereas low-acid products can be processed through indirect systems using tubular or plate heat exchangers, or through direct steam injection or infusion systems. Clear high-acid products such as apple juice can be processed through either plate or tubular aseptic processors, whereas the presence of either short or long fibers in the juice may direct the design team to select a tubular unit or an aseptic processor that includes a wide-gap plate heat exchanger.

Viscosity

Products that possess low viscosity such as fluid milk, soymilk, etc. can be easily processed using UHT processors that employ plate heat exchangers or through aseptic processors that use direct steam injection. As the viscosity of the product increases to heavier creamy products, certain high-viscosity mixes, custards, etc., the choice of processor also switches to indirect aseptic processors. Usually, tubular UHT processors are better suited for products that have a higher viscosity, or for products that have added fibers or suspended particulates. In the extreme case of high viscosity low acid products that contain large suspended particulates, you may consider using aseptic scraped surface heat exchanger units to ensure adequate heat transfer.

Sensitivity to heat damage

Products such as fluid milk, ice cream mix, or shake mix, can react differently during thermal processing. Different food constituents react differently during thermal processing. For example, different proteins denature at different temperature/time combinations. Also, during UHT processing some of chemical reactions, such as browning reactions or caramelization of sugars, may take place. Generally, the thermal damage and/or the extent of undesirable chemical reactions are least significant in the case of direct steam injection systems when compared to indirect aseptic processors. Furthermore, some of the undesirable flavor compounds that may form during processing are commonly removed as the finished product goes through the flash chamber, leaving a cleaner flavor profile.

Choose the best for the application

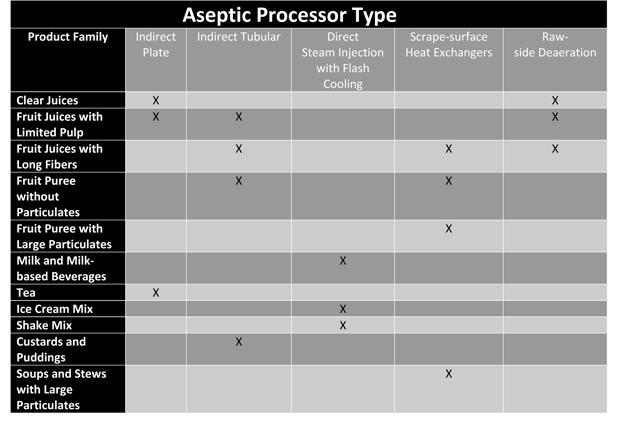

There are many different Direct and Indirect Processor designs for the production of Aseptic Beverages for High and Low Acid products. Some are more energy-efficient than others, and others may not be as energy-efficient but yield a fresher taste and do a better job at maintaining the nutrients. At JCS, we provide you a customized system to meet the specific needs of your applications. Below is a table that shows JCS best-suited technology recommendations based on your application.

At JCS our processing systems are built with a maximum of flexibility, configurability, and customization, accommodating many changing parameters, to perfectly fit your specific processing needs. Together JCS will partner with you to form a winning team to implement the most value-added, and sustainable solutions to ensure long-term success and profitability for your organization. Contact us today to learn more!