Electrical safety is of vital importance in plants and workplaces around the industry. Failure to comply with published guidance, regulations, and standard industry practices can lead to avoidable injuries including: shocks, burns, and deaths from electrocution. The data shows that in overall safety numbers, 1 in 300 recordable injuries will result in death. If we look at the electrical safety numbers, we see 1 in 13 electrical related recordable injuries result in death. Electrical safety is important to JCS because electrical injuries impose huge personal and organizational tolls, often lead to longer than usual hospital stays, and can permanently alter the injured person’s life.

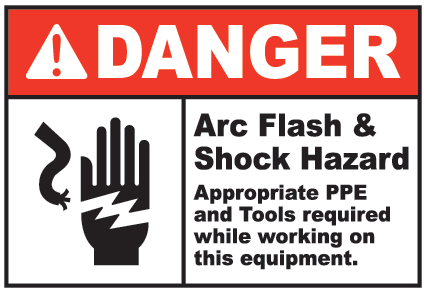

JCS has made a commitment to our employee team members and our customers that our on-site service technicians and field engineers will accomplish 30 hours of training through an Occupational Safety and Health Administration (OSHA) authorized course. In addition, the on-site employees receive National Fire Protection Association (NFPA) 70E training on how to identify electrical hazards, to include shock, arc flash, and arc blast, how to address and mitigate those hazards, and the proper use of tools and personal protective equipment (PPE) when working with or around potential shock, arc flash, and arc blast hazards.

http://www.safetysign.com/images/source/large-images/J5538.0e5604f912273ef185ac02e47b9a1bbb.png

http://www.safetysign.com/images/source/large-images/J5538.0e5604f912273ef185ac02e47b9a1bbb.png

At JCS, we identify the electrical hazard by having a trained and “qualified person” on-site. NFPA 70E defines a qualified person as “one who has demonstrated skills and knowledge related to the construction and operation of electrical equipment and installations and has received safety training to identify and avoid the hazards involved.”

Our on-site team addresses and mitigates the associated hazards to ensure an electrically safe working condition by adhering to NFPA 70E 130.2 which states, “energized electrical conductors and circuit parts shall be put into an electrically safe work condition before an employee performs work if any of the following conditions exist:

- The employee is within the limited approach boundary.

- The employee interacts with equipment where conductors or circuit parts are not exposed but an increased likelihood of injury from an exposure to an arc flash hazard exists.”

Lastly, JCS personnel carry the appropriate tools and PPE to the job site and review the requirements or NFPA 70E, 130.4 for shock protection and 130.5 for arc flash risk assessment prior to beginning the work.

Take the time to be electrically safe and avoid accidents.