We Know How

Milk, Shake Mix, Ice Cream Mix, Functional Beverages, Plant Based Beverages, Nut based Beverages, Fruit Juices, Nectar, Tea, Sauces, Purees, and many other types of foods and beverages.

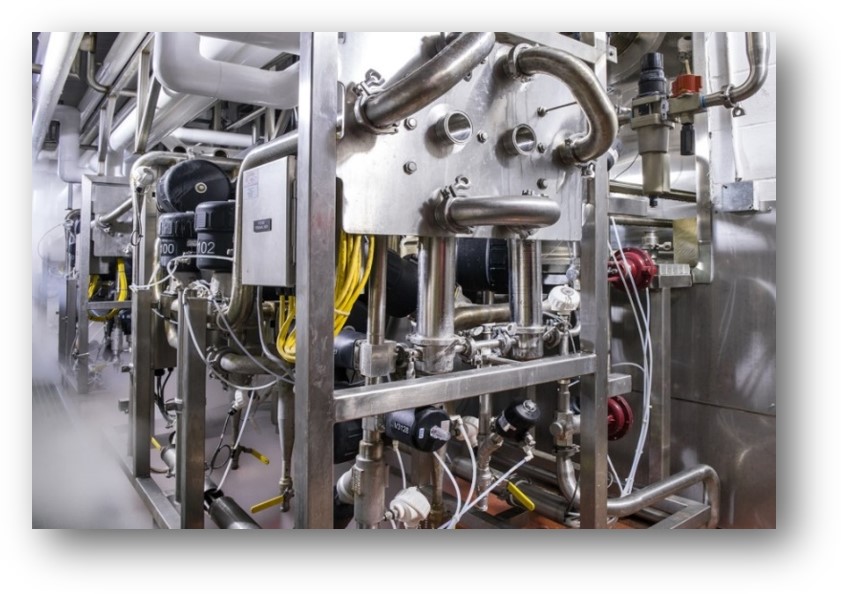

The JCS UltraBlock™ is an Aseptic Isolation Valve Cluster that provides an aseptic barrier to protect the integrity of aseptically processed products. It is placed between the processor (HHST, UHT, or HTST with MST) and the Sterile Product Surge Tank (AsepTank™) thus protecting either side of the UltraBlock™ from the other when:

With the JCS UltraBlock™ you can minimize product losses by letting the processor transition from product to product, without having to go product to water.

The JCS UltraBlock™ maintains the integrity of product and sterility on either side of the barrier between the UHT and the Aseptic Surge Tank. This maximizes product runs, ensures the separation of incompatible products, coordinates all functions with the filler, and can be fed to multiple destinations.

Compact Design – The skid contains the UltraBlock™ cluster, sterile air header for AsepTank™ and is prewired to an electrical enclosure. Our design minimizes floor space, while making sure all valves are easily accessible for maintenance.

Ease of Integration – The Control System provides an Ethernet Connection to the Plant PLC network and provides a protocol for synchronizing control of the Upstream Processor and Down Stream Fillers, as well as the CIP System.

On-site Start-up Time – only 5 days which includes the complete PMO validation.

HAACP Screen – A single HMI screen displays all of the Critical Control Points (CCP) making the data easily accessible for Quality Control to review.

Maintainable – the JCS supplied aseptic valves are the most suitable valve for this aseptic application. Rated for full vacuum and, full steam pressure. Only the diaphragm in contact with the product so no need for additional valve steam seals.

PMO, USDA, and 3A Compliant – Meets criteria for Low and High Acid aseptic product and chemical isolation.

JCS Process & Control Systems • 172 Metro Park, Rochester, NY 14623 • p: 585-227-5910 • f: 585-723-3213

© 2026 JCS All rights reserved Site Map