Visit UltraPhil.com

The state-of-the-art UltraPhil Center for Aseptic Excellence is officially open and ready to support your future beverage projects. As a fully FDA validated, licensed beverage facility, we can:

Replicate any current commercial aseptic beverage process (fluid milk, protein, coffee, tea, juice, and more).

Optimize product/process design to find the right combination for ultimate commercial success.

Prove scalability and commercial manufacturability faster and more efficiently.

Secure your 2026 UltraPhil dates now. Capacity for your next breakthrough product is filling up quickly!

After five decades of reliable service, Rockwell Automation has officially stopped servicing RSLogix 5 and ended all new sales and improvements for the PLC-5 platform. This means that if your system goes down, the clock is ticking against a lack of official support and dwindling spare parts.

Don't wait for a failure to force your hand. Start a proactive conversation about your migration strategy. JCS is here to ensure your transition is seamless. We specialize in modernizing legacy systems without the headache of extended downtime.

As a Rockwell Systems Integrator, at JCS we have the industry and system expertise to design, build, install, maintain and support your automation solutions.

Our goal is to help you develop the best possible solution with the least amount of risk for your company.

-1.png)

The results are in! JCS is proud to be named the 3rd fastest-growing privately owned company by the Greater Rochester Chamber. Achieving a Top 3 placement is a major milestone and underscores our commitment to excellence and innovation in the Greater Rochester area.

This prestigious recognition is a testament to the hard work and dedication of our team and the trust of our clients. Thank you for being a part of our incredible growth journey.

JCS specializes in advanced process and control systems design, focused on the Food & Beverage (F&B) industries. We know how to help you maximize your Return on Investment (ROI) while putting high quality and great taste into every product you produce.

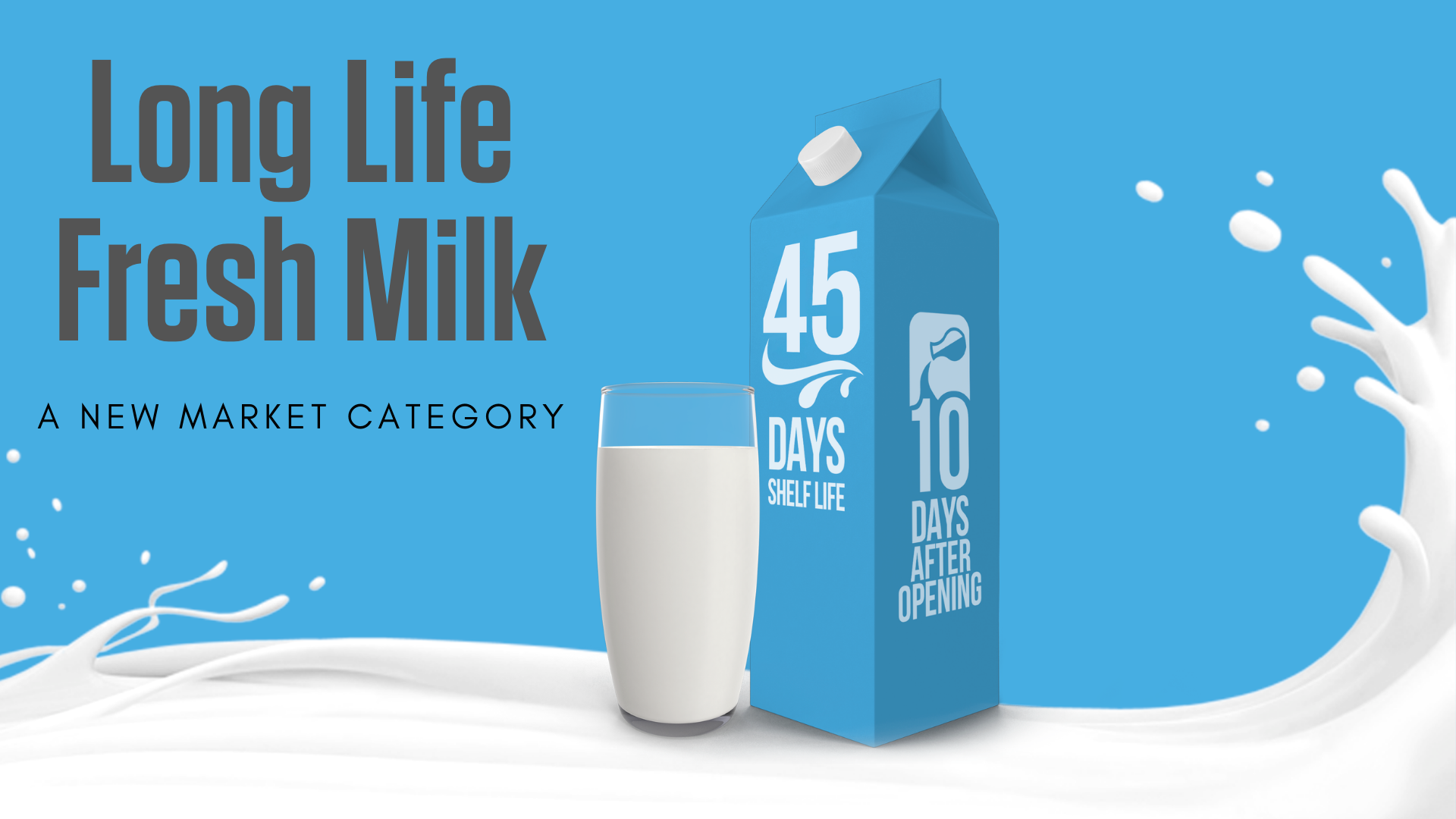

MST is a revolutionary new and patented technology that integrates with the traditional HTST Fresh Milk processes to produce long life product with all the same nutritional values that consumers of fresh milk desire.

The Ultra Family of Products deliver solutions for shelf stable and extended shelf life products with stability, safety and superior quality.

Milk, Fruit Juices, Spirits, Shake Mix, Ice Cream Mix, Functional Beverages, Plant Based Beverages, Nut based Beverages, Nectar, Tea, Sauces, Purees, and many other types of foods and beverages.

Unlike ratio flow control solutions that give away product valuable components like Fruit Solids or Milk Butter Fat, JCS accurately standardizes product to the components within each metered flow stream. This results in a continuously blended product standardized to the sub-component being measured, allowing for product targets to be set to the bottom end of the quality control range. I.E. +-0.001% salt, or +- .02%BF, or +-.03%ABV etc.

JCS product portfolio includes:

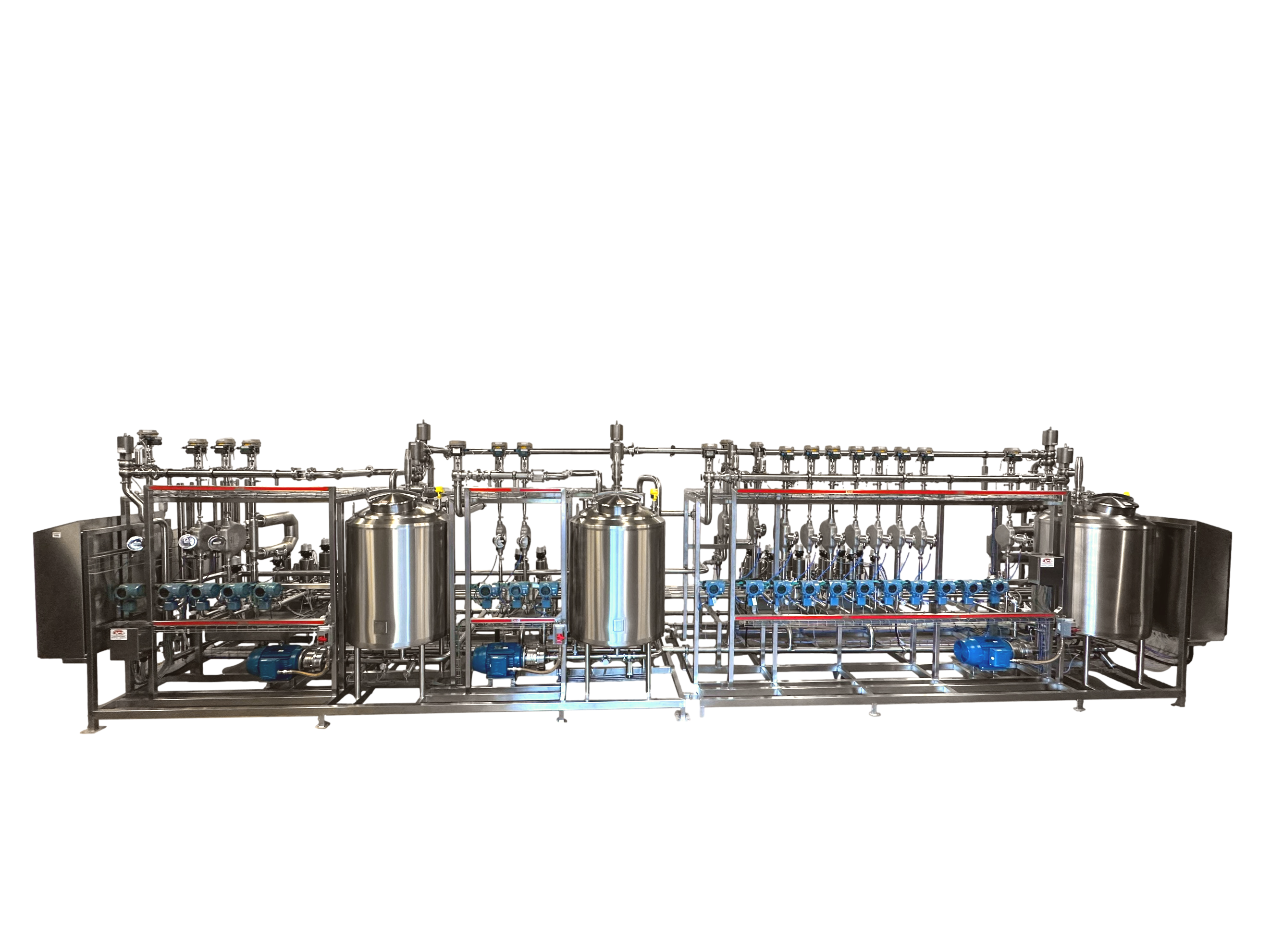

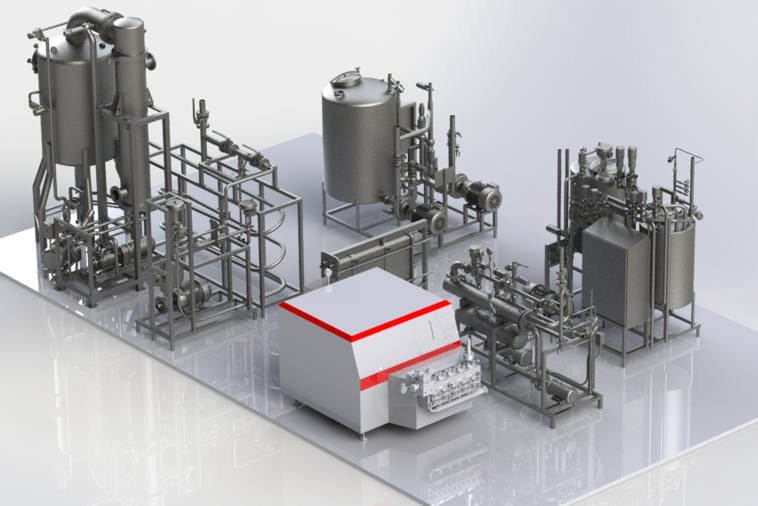

Ultra Family of Products: Pasteurization systems for Aseptic or Extended Shelf Life (ESL)

Milk

Fruit Juices

Spirits

Shake Mix

Ice Cream Mix

Functional Beverages

Plant based Beverages

Nut based Beverages

Nectar

Tea

Sauces

Purees

and many other types of foods and beverages.

JCS brings you service expertise and approaches that keep you up and running with ultimate quality and productivity.

Posted June 19, 2024

California Dairies selects JCS for design, engineering, and processing technologies for new milk bottling facilityJCS Process & Control Systems has been awarded a contract by California Dairies, Inc. (CDI) – the largest California farmer-owned dairy cooperative and second largest in the United States – to support the total process design, engineering, fabrication, installation, and commissioning of a new 200,000-square foot milk processing plant (phase 1) in Bakersfield, California.

Posted June 14, 2024

RECAP of the 2024 Annual JCS Charity Golf Tournament in KentuckyOn June 7th, JCS hosted its Annual Charity Golf Tournament in Bardstown, Kentucky, benefiting the Wounded Warriors Foundation and what an incredible day it was! This year we had a larger group of Distillers and Sponsors come together and spend a sunny day at Bardstown Country Club golf course. The day was filled with friendly competition, valuable conversations, and memorable moments with colleagues from the bourbon industry.

Discover the unsurpassed know-how of JCS and all the ways our analyze/design/deliver approach can provide superior processing solutions.

Discover the unsurpassed know-how of JCS and all the ways our analyze/design/deliver approach can provide superior processing solutions.

View or download PDFs

JCS Process & Control Systems • 172 Metro Park, Rochester, NY 14623 • p: 585-227-5910 • f: 585-723-3213

© 2026 JCS All rights reserved Site Map