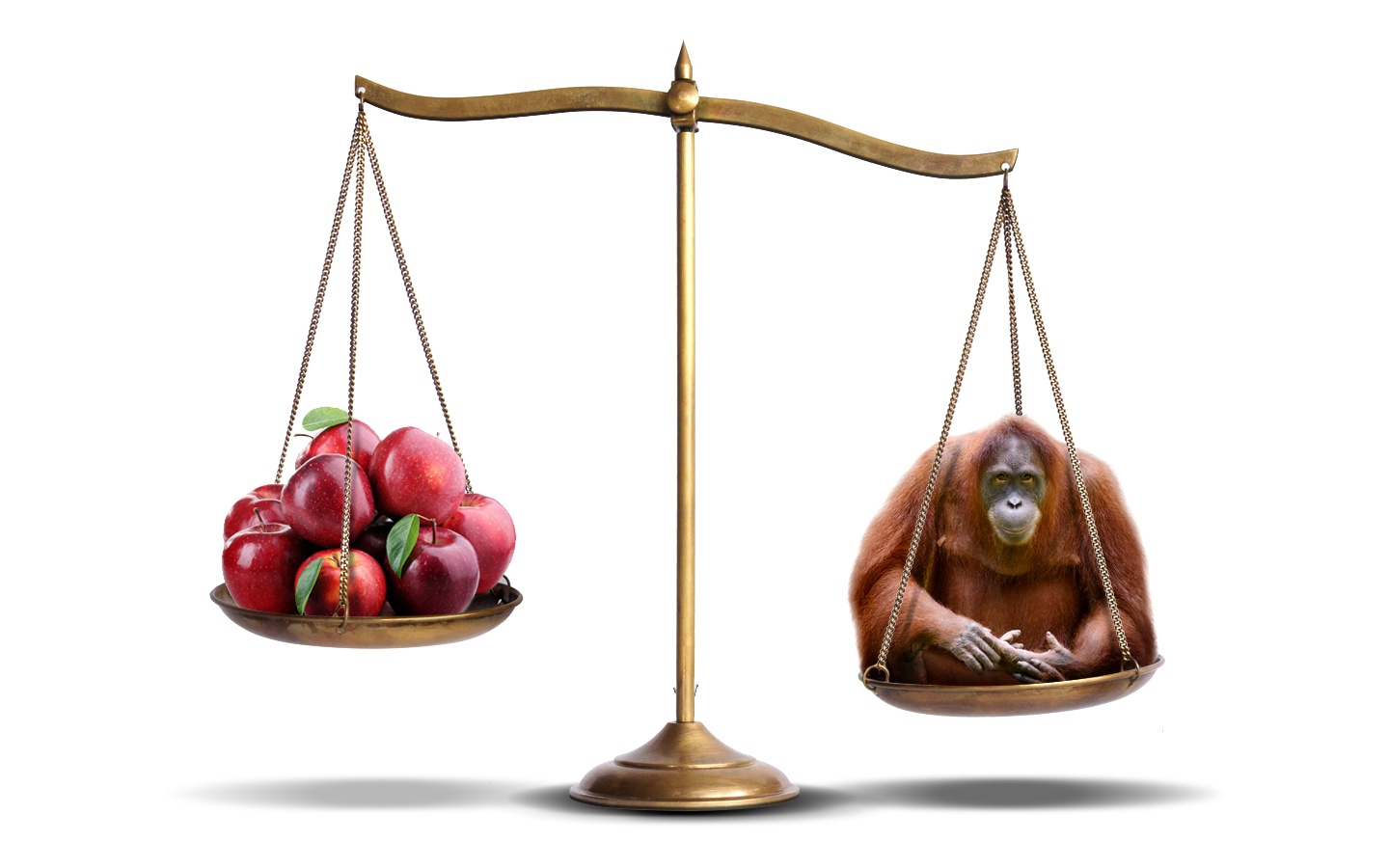

When it comes to evaluating vendor proposals for a capital project, just comparing the price tag could be as unequal as comparing apples to orangutans. For example, two processing lines may contain the same throughput, the same equipment, and even look the same; this does not necessarily mean that they are the same. Capital projects should be compared based on the return on investment (ROI) that you gain from the implementation of the project.

When it comes to evaluating vendor proposals for a capital project, just comparing the price tag could be as unequal as comparing apples to orangutans. For example, two processing lines may contain the same throughput, the same equipment, and even look the same; this does not necessarily mean that they are the same. Capital projects should be compared based on the return on investment (ROI) that you gain from the implementation of the project.

To have a true comparison, we need to complete a process evaluation to determine the total cost of ownership (TCO) for each process. This means that the cost of running the line, the yields of the line, the uptime of each, the manpower required to operate the line, and the utilities required for each must be calculated. If you are working with a valued partner there should be no problem obtaining this data for the proposed offering; conversely if you are simply working with a vendor, the data may not flow so freely.

The real story may take some legwork on your part, but the savings could make or break a project success in the long run. A spreadsheet is your best friend in this endeavor, make a side by side comparison of all the aspects of the project; purchasing, installation, startup and commissioning, utilities required, operating, required manpower, yields, training, and maintenance. Once you have this spreadsheet compiled, compare the TCO against the benefits gained from the project; ie. new product launch, additional capacity sold, or whatever is your benefit. The comparison will be your ROI, this will give you a true evaluation of competing offerings.

Evaluate every aspect of the cost for the new line; request the data from your partner supplier, and have the critical components guaranteed. At JCS we guarantee the waste of interfaced lost product on a changeover; does your vendor offer that level of confidence for your project? We may not be the lowest cost option from a sticker price; however, it is not uncommon for a JCS processor to have a lower total cost of ownership by hundreds of thousands of dollars a year, in fact in several systems JCS has a TCO lower than our competition of more than 1 Million Dollars per year. The ROI for the project may be in months instead of years, make sure you are evaluating the project for its true costs.