We Know How

JCS has announced plans to open the UltraPhil Center for Aseptic Excellence, the world’s first and only small scale, bottle-based pilot aseptic research, development, and production center.

UltraPhil will be a strategic resource for research and development, product development, and ingredients and packaging personnel from across the global aseptic beverage formulation and processing industry.

As a Rockwell Systems Integrator, at JCS we have the industry and system expertise to design, build, install, maintain and support your automation solutions.

Our goal is to help you develop the best possible solution with the least amount of risk for your company.

-1.png)

We are thrilled to announce that JCS has been nominated as part of the Rochester Chamber Top 100 Companies.

During the award ceremony, we ranked #18 as part of the fastest-growing privately owned companies in the Greater Rochester region.

This is exciting news for JCS, and we are striving to continuously support the development of the Rochester region with the amazing support from our employees and customers!

-1.png)

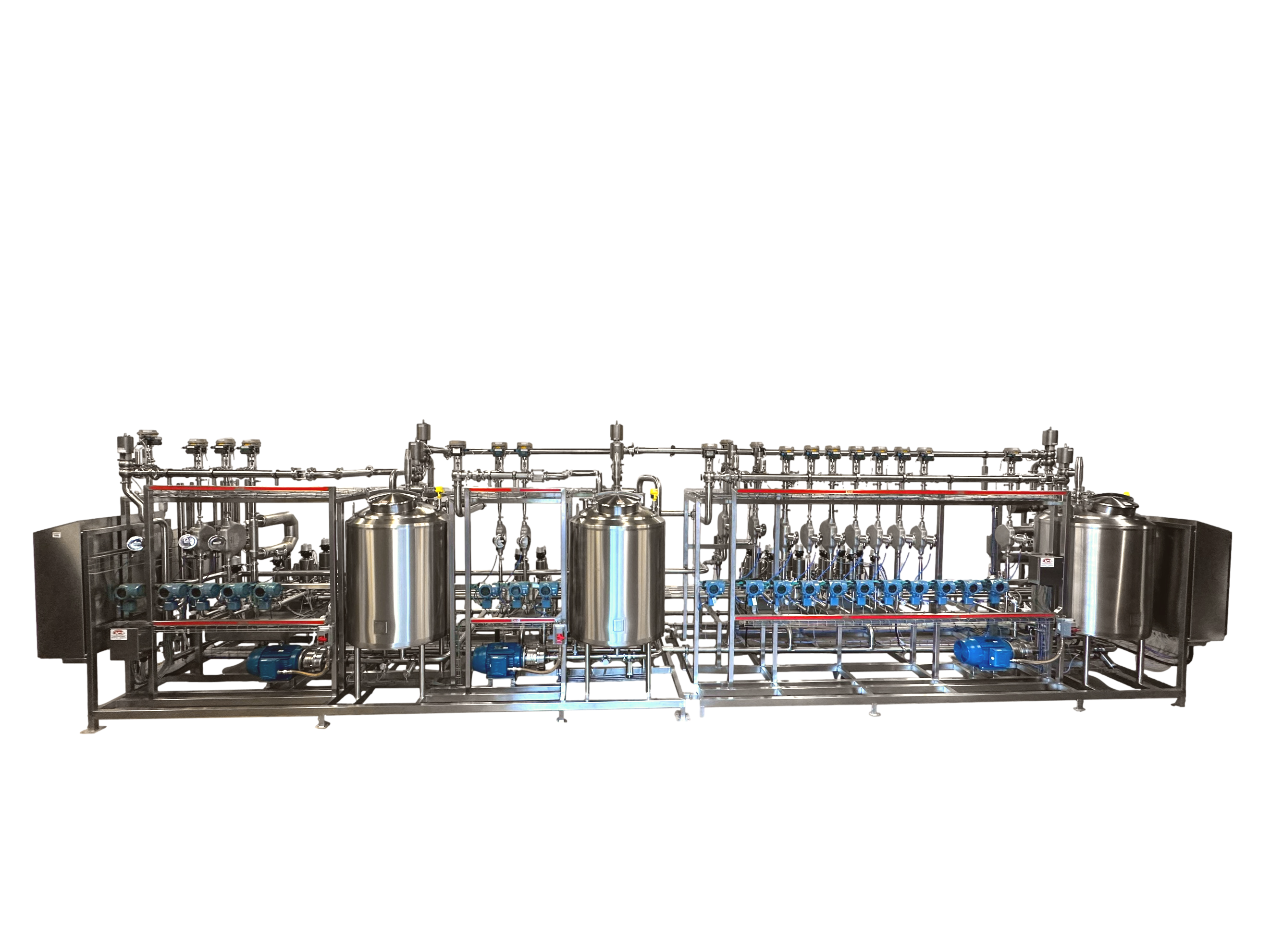

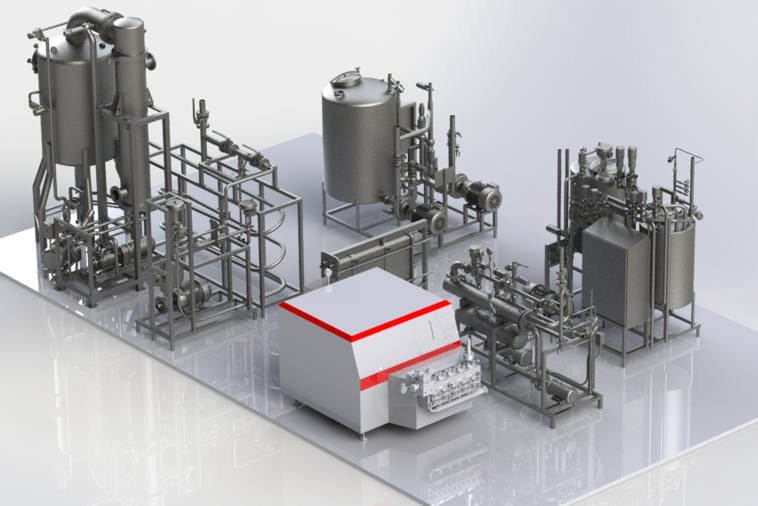

JCS specializes in advanced process and control systems design, focused on the Food & Beverage (F&B) industries. We know how to help you maximize your Return on Investment (ROI) while putting high quality and great taste into every product you produce.

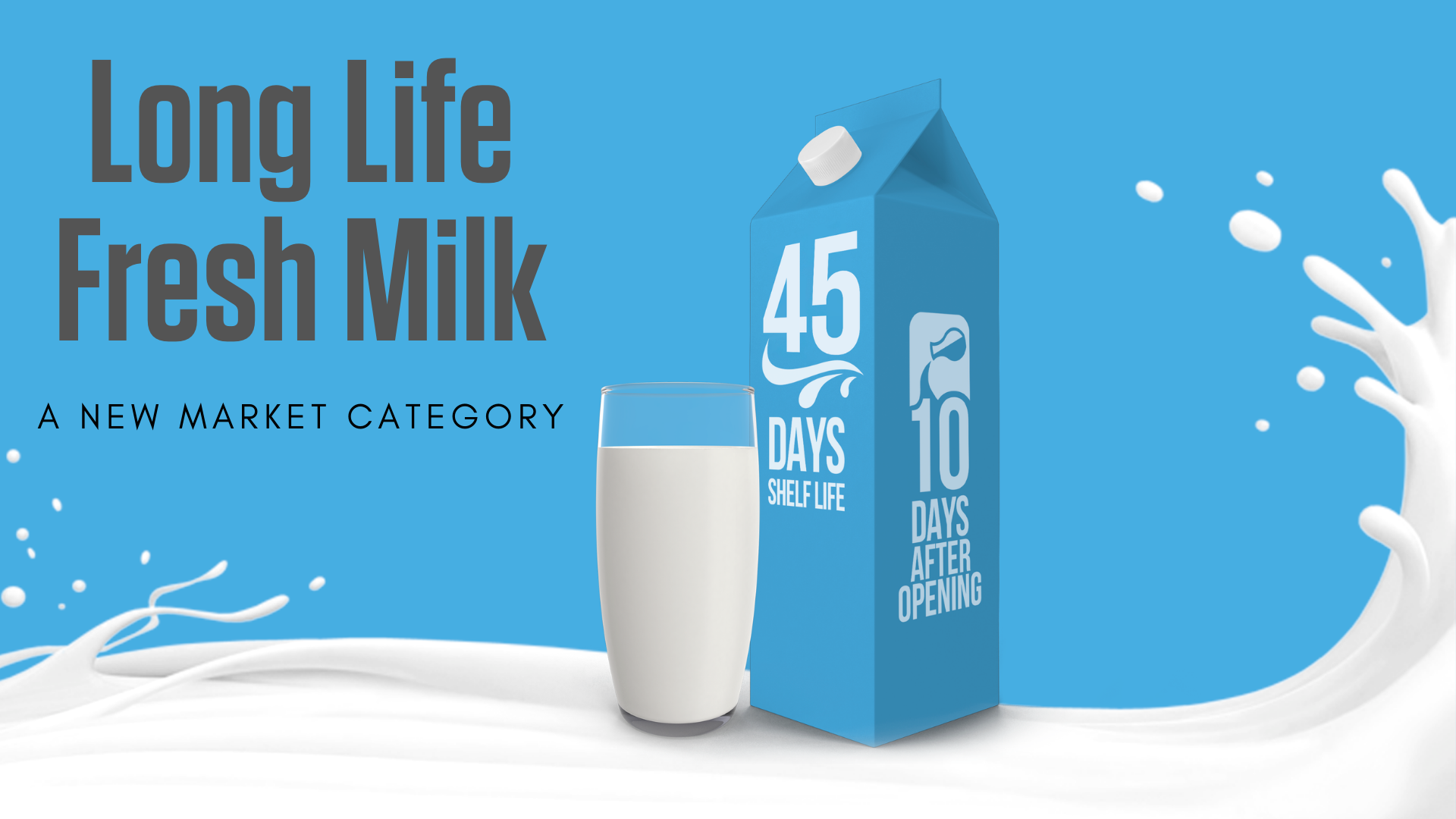

MST is a revolutionary new and patented technology that integrates with the traditional HTST Fresh Milk processes to produce long life product with all the same nutritional values that consumers of fresh milk desire.

The Ultra Family of Products deliver solutions for shelf stable and extended shelf life products with stability, safety and superior quality.

Milk, Fruit Juices, Spirits, Shake Mix, Ice Cream Mix, Functional Beverages, Plant Based Beverages, Nut based Beverages, Nectar, Tea, Sauces, Purees, and many other types of foods and beverages.

Unlike ratio flow control solutions that give away product valuable components like Fruit Solids or Milk Butter Fat, JCS accurately standardizes product to the components within each metered flow stream. This results in a continuously blended product standardized to the sub-component being measured, allowing for product targets to be set to the bottom end of the quality control range. I.E. +-0.001% salt, or +- .02%BF, or +-.03%ABV etc.

JCS product portfolio includes:

Ultra Family of Products: Pasteurization systems for Aseptic or Extended Shelf Life (ESL)

Milk

Fruit Juices

Spirits

Shake Mix

Ice Cream Mix

Functional Beverages

Plant based Beverages

Nut based Beverages

Nectar

Tea

Sauces

Purees

and many other types of foods and beverages.

JCS brings you service expertise and approaches that keep you up and running with ultimate quality and productivity.

Posted December 5, 2023

JCS Process & Control Systems to open UltraPhil Center for Aseptic ExcellenceJCS has announced plans to open the UltraPhil Center for Aseptic Excellence, the world’s first and only small scale, bottle-based pilot aseptic research, development, and production center.

UltraPhil will be a strategic resource for research and development, product development, and ingredients and packaging personnel from across the global aseptic beverage formulation and processing industry. UltraPhil will support a broad array of beverage product formulations including fluid milk beverage products, protein based low/high acid beverages, plant-based protein drinks, dairy and non-dairy based coffees and teas, nutritional drinks, 100% juice and juice drinks, as well as sports drinks.

Posted August 3, 2023

Successful JCS Golf Tournament in Kentucky A great time was had at the first annual JCS Golf Tournament hosted at My Old Kentucky Home golf course in Bardstown, Kentucky. This event brought many local distillers and JCS partners together to benefit the Lifting Spirits Foundation, a non- profit organization that supports workforce development issues and initiatives within the distilled spirits industry. We’re proud to say this event raised $8,320 for the Lifting Spirits Foundation, and cheers to all those involved. Discover the unsurpassed know-how of JCS and all the ways our analyze/design/deliver approach can provide superior processing solutions.

Discover the unsurpassed know-how of JCS and all the ways our analyze/design/deliver approach can provide superior processing solutions.

View or download PDFs

JCS Process & Control Systems • 172 Metro Park, Rochester, NY 14623 • p: 585-227-5910 • f: 585-723-3213

© 2024 JCS All rights reserved Site Map